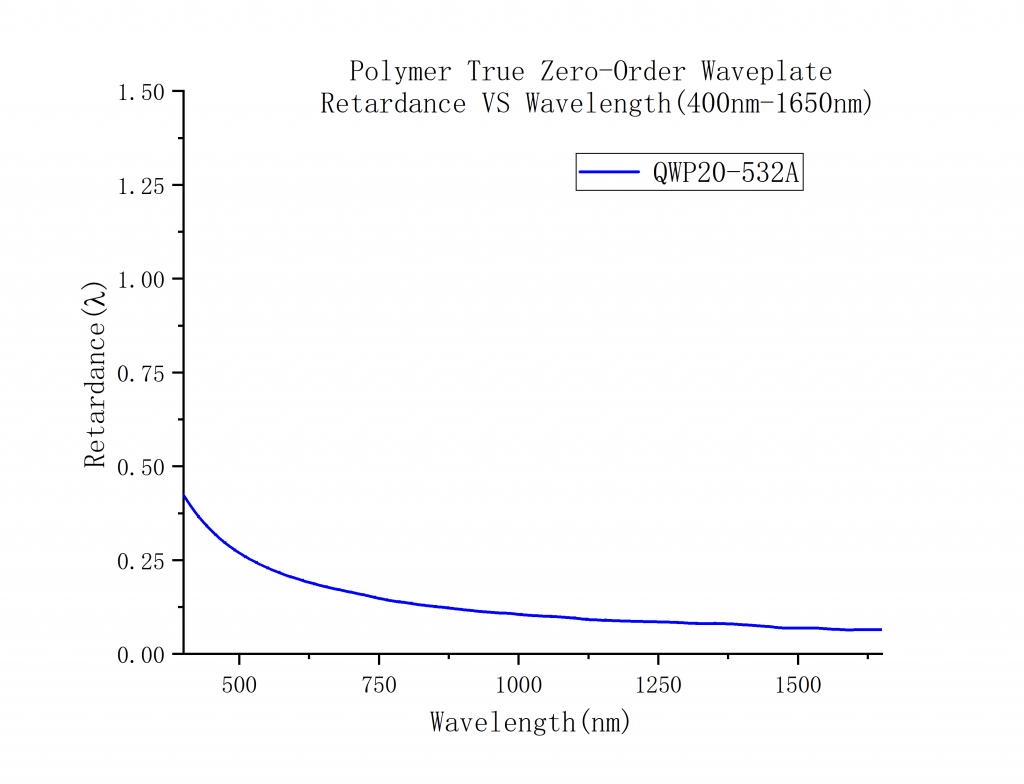

The CRYLINK liquid crystal polymer wave plate is composed of two N-BK7 window sandwiches with precise thickness birefringent liquid crystal polymer film, which is pre installed in the standard SM1 lens sleeve. The outer surface of lens sleeve is engraved with product model and wave plate quick axis marking line, which is convenient for customers to distinguish and use. By precisely controlling the thickness of liquid crystal polymer, the optical path difference (or phase difference) produced by the light (o-ray) and the parallel optical axis (e-ray) can be precisely controlled. A beam of linear polarized light is vertically incident on a quarter of the wave plate. The angle between the light vector of the incident linear polarized light and the fast axis of the wave plate is a. the vibration direction of the incident light is divided into two components perpendicular to the optical axis and parallel to the optical axis. The light of two components propagates in the same direction. The optical path difference between the two components after passing through the wave plate is: (no -ne)*d=λ/4. Where D is the thickness of the wafer, no and ne are the refractive indices of o and e light. Then the phase difference between two components perpendicular to each other: δ=(2π(no -ne)*d)/λ=π/2. When the angle between the polarization direction of the incident beam and the fast axis of the quarter wave plate is 45 degrees, the incident beam will transform into circularly polarized light after passing through the quarter wave plate.

Parameter

Basic Parameters

| Material | Liquid crystal polymer |

| Product ID | PB07004 |

| Surface quality | 40/20 |

| AOI | ±15° |

| Retarda-tion | λ/4 |

| Retarda-tion tole-rance | ±λ/100 |

| Thread specification | SM1 Internal and external threads |

| Thickness tolerance | ±0.05 mm |

| RMS | ±5 nm |

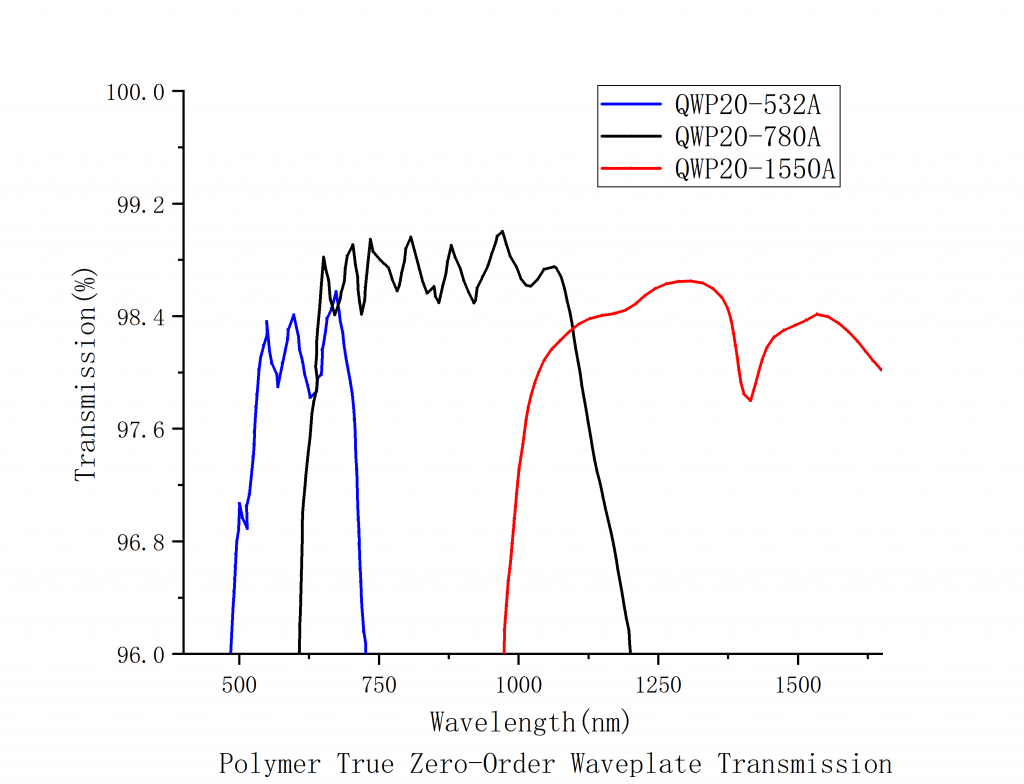

| Design wavelength | 398 nm,405 nm,420 nm,442 nm,488 nm,520 nm,532 nm,633 nm,670 nm, 780 nm,795 nm,796 nm,800 nm, 808 nm ,850 nm,905 nm,980 nm,1030 nm,1053 nm,1064 nm,1310 nm,1550 nm |

| Clear aperture | Ø 21.5 mm |

| Transmitted light deflec-tion | <10 arcsec |

| Working tempera-ture | -20~60°C |

| Diameter of mechani-cal shell | 30.5 mm |

| Diameter tolerance | +0.00/-0.05 mm |

Application

- Circular polarizer

- Optical attenuator

- Optical isolator

Feature

- The wavelength sensitivity of delay is low

- High temperature stability

- The effective angle of acceptance is large